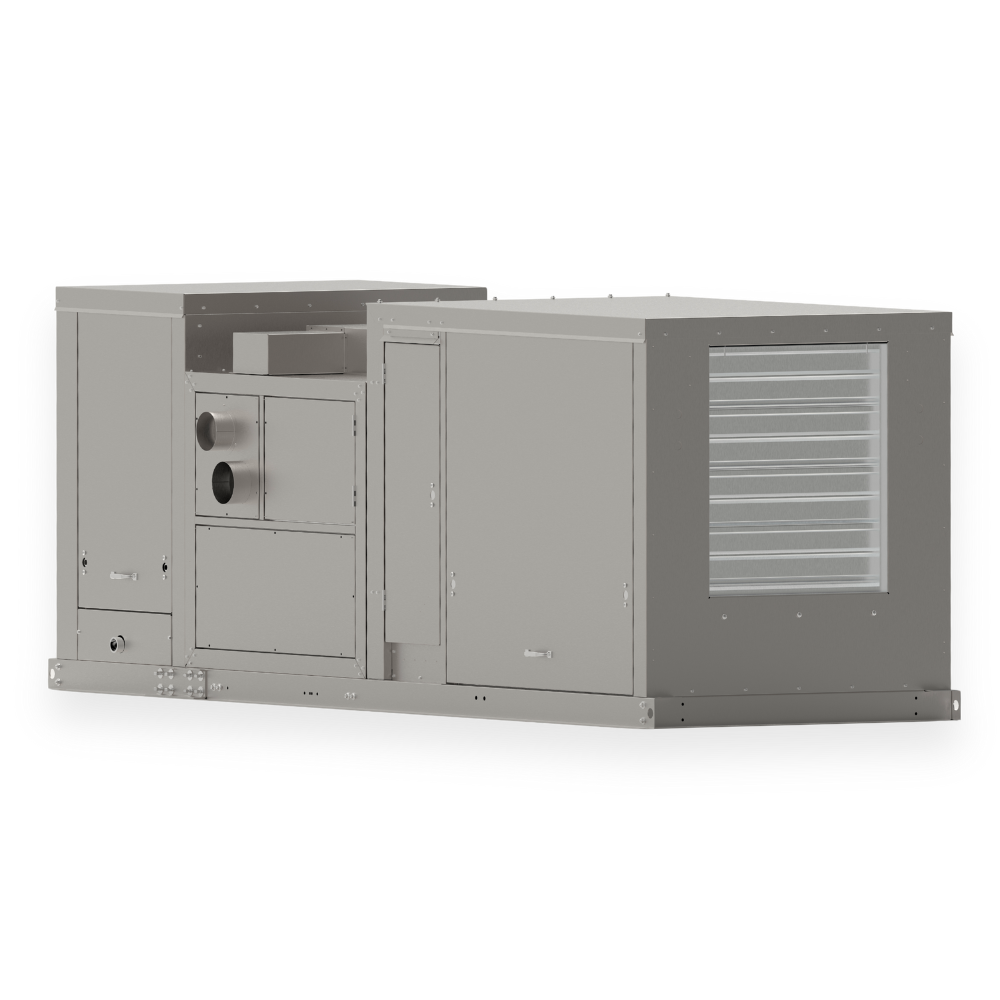

Indoor Separated Combustion Duct Furnace

Modine’s indoor gas-fired system units deliver reliable, high-efficiency heating for commercial and industrial applications. Designed for flexibility and performance, these duct furnace and blower systems are available in separated combustion (DBS/DCS) models, with optional cooling coil sections for year-round climate control.

Separated Combustion systems are designed for buildings with hostile atmospheric conditions, drawing 100% fresh outside air for combustion. Perfect for dusty, humid, or dirty environments, they feature fully gasketed doors to protect internal components and help eliminate off-cycle heat loss, making them a top choice for harsh conditions.

With 80% thermal efficiency, multiple model sizes (100,000–1,200,000 BTU/hr), and customizable configurations, these systems are engineered to meet your unique heating and make-up air needs, backed by the durability and quality you expect from Modine.

Available Models

DBS (Indoor separated combustion system with blower)

DCS (Indoor separated combustion system with blower and coil cabinet)

- Available in 17 model sizes with input ranges from 75,000 to 1,200,000 Btu/Hr.

- Airflow ranges from 556 to 14,500 CFM

- Natural or propane gas

- All units a minimum of 81% thermally efficient

- 20°-100°F air-temperature

- ETL certified

- Superior corrosion resistance and extended equipment life with 18-gauge, polyester-powder paint on an aluminized steel blower casing and 20-gauge aluminized steel cabinet on furnace

- Blower and motor vibration isolation

- Blower performance up to 3.0” W.C. is perfect for longer ductwork or accessories with high-pressure drops

- Quick and accurate field connections with separate line and low-voltage terminal strips with job-specific wiring diagrams

- Separate electrical, venting, and gas control access with fully gasket-installed doors

- Designed, Engineered & Assembled in the USA

- 409 stainless steel heat exchanger, burner, and drip pan

- Two-stage and electronic modulation controls

- Modine Control System option provides a programmable microprocessor controller with building management compatibility

- High and/or low gas pressure switches

- Ultra-low leak class-I leakage resistance outside air dampers

- Two position, modulating, or floating building pressure control damper actuators maximizes control of outside ventilation air with fresh and return air dampers

- Variable frequency drives for maximum air volume control flexibility

- Factory-installed DX or chilled water coil

- Dead-front disconnect switches

- Double-wall construction for the blower and/or cooling cabinet

- Circuit analyzers minimize start-up and service time by immediately identifying causes of improper unit operation

- Smoke detectors, timed freeze protection, thermostats, time clocks, and many other control devices